A company that has been active in the development of 2D and 3D CAD software for over forty years, with façade construction as its core business, is ISD Group. It focuses on manufacturing companies to make the step to BIM easier. Thermo Konstrukties from Cuijk is one such company. They design, produce and install top-quality aluminium windows, doors and curtain walls.

Started in the private market, but now 80% of the work is done in utility construction. "A conscious choice," says Ramon Koenen, technical director at Thermo Konstrukties. "Larger, more challenging work and especially the specialism appeals to us enormously. We have invested in machines, knowledge and skills and now work with a fixed group of contractors. Increasingly, it is required that you work with BIM, so we were looking for a party that could help us make that step."

Trial period

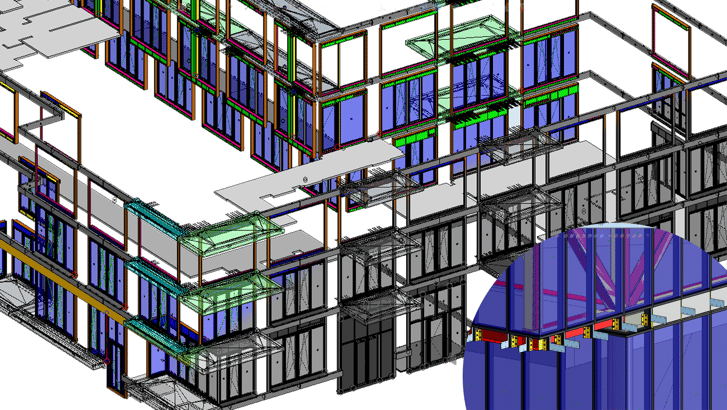

When asked how Thermo Konstrukties ended up with ISD, Koenen answers: "ISD was at the table of our regular aluminium supplier - Reynaers - and the link was quickly made. A five-month trial period for the HiCAD software followed and we immediately started the training course in order to master the software as quickly as possible. And then a project came our way in which BIM was required and there was considerable time pressure. We had the choice: outsource or do it in-house but take on this Van der Landen project during the trial period... we chose the latter. There really were some struggles behind this, says Koenen. "During the course, the drawing work went very well from the start, but the data exchange with the contractor was initially difficult because they did not work with HiCAD. It is great to see that ISD is on hand to help find solutions. Koenen looks back on the intensive trial period with a good feeling: "There was healthy pressure from both sides, but if you get through it well, you immediately know what you can expect from each other.

Extremely detailed

Meanwhile, Thermo is making full use of HiCAD. "Modelling is fairly new for us, but the detailed level (1:1 scale) in HiCAD is exactly what we need. ISD's temporary work-around that allows files to be displayed properly for contractors will later be incorporated into the software as standard. The constant further development by ISD ensures that it keeps getting better. Everyone at Thermo is enthusiastic about HiCAD. "Without having to make mega investments in hardware, HiCAD works very smoothly, even with large files in these kinds of large projects." The fact that there is no need for separate modelling and the speed with which frames and elements can be converted into 3D was another reason for choosing HiCAD. "After it is drawn in 3D, it is transferred directly to the machines in the production hall, which reduces the risk of errors."

The constant further development by ISD ensures that it gets even better. Thanks to this software, we meet the BIM requirements. We have even advised our competitors to switch to HiCAD.

Ramon Koenen, Technical Director at Thermo Konstrukties

BIM

Koenen is convinced that the investment in HiCAD was well worth it. "Thanks to this software, we meet the BIM requirements. This way of working suits us perfectly: Not only do we draw spatially, but also think spatially, which allows us to identify issues early on. Our people's eagerness to learn and enthusiasm is enormous, which is why we were able to use it so quickly." Thermo has now switched completely to three licences and has also purchased the plate module. A logical next step, according to Koenen. "In time, we will be able to send our sheet metal work directly to the production department. He concludes: "We are enthusiastic, about the software and about the service from ISD. We have even recommended HiCAD to two competitor companies.