Compri Aluminium describes its services as an innovative wholesaler and manufacturer. The specialist in aluminium profiles and sheet metal for roofs, facades and solar panels not only supplies standard solutions, but is also strong in customised work. For this, the company has relied on ISD Group software HiCAD for many years, to which HELiOS has recently been added. An interview with Miranda de Boer-Prinsse, engineer at Compri Aluminium.

With a large range of standard profiles for water barriers, drip caps, roof trims, solar mounting material, facade cladding, flashings and much more, Compri Aluminium is an established name in the market. "If required, we can also supply all these products to order if a project cannot be carried out using a standard profile. We often help our customers out," Miranda laughs. "My work mainly consists of translating an architect's ideas, which are not always practical, into a feasible concept."

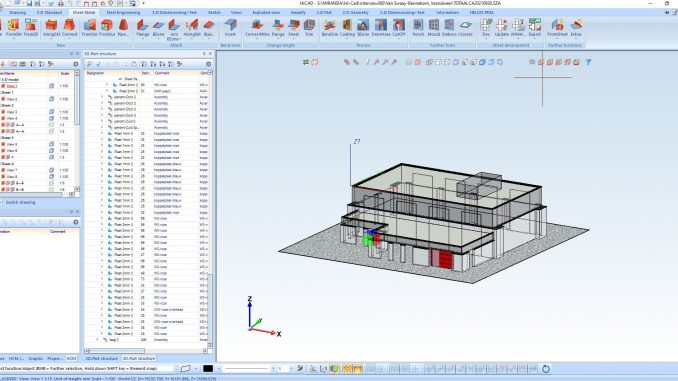

Compri Aluminium has been working with HiCAD from ISD Group since 2013. " We used to draw in AutoCAD, but that was time-consuming because all the views had to be drawn separately. In HiCAD, we draw in 3D and can generate the 2D sections and views directly from the model. This not only saves time, but also eliminates errors. Another advantage of HiCAD is that we can visualise any bottlenecks during the elaboration in 3D to our clients. That gives a much better insight. All connections and possible bottlenecks are already tackled in advance, so that the assembly on site runs smoothly. Because the drawing already gives us an insight into the plate dimensions required to carry out the customised work, we can already take into account the maximum dimensions of the plate, the bending machine, the punching machine and the powder coating line. In HiCAD, we have been able to create our own profiles in a catalogue, which makes it easy to draw the connections between the bending work and these profiles, or to separate corners. Customised profiles with the same basic assumptions can now be entered parametrically, which makes drawing much faster. Since last year, we have also been using HELiOS, mainly for managing all documents," Miranda continues. "The link with HiCAD ensures, among other things, that we can manage item numbers better and that a change in a drawing is immediately copied to all other related drawings. There is also a complete overview of the status of a drawing: whether it is under review or already approved. Moreover, there is always an overview of the most recent version of a drawing."

Drawing in HiCAD enables us to process more orders by working smarter, not harder".

Some examples of recent projects worked out by Compri Aluminium in HiCAD include Talent Square in Tilburg, the fire station in Bennekom, Thema Dreven in Utrecht and the AZ training complex in Wijdewormer. "For the first project, a large quantity of frames was produced to give the window frames the appearance of a bay window or a pop-out window," says Miranda. "For this purpose we have 'contoured' the profiles. Because of the size, a mock-up was made in advance to check all the details and fine-tune them where necessary. For the fire station in Bennekom, we designed wall copings in HiCAD that run seamlessly into the water barriers. Because of the variation in wall width and changing connections, it was quite a job to engineer the elements in such a way that they would not warp. For the project in Utrecht, on the other hand, we designed an extrusion profile in connection with the length, depth and assembly of the custom work and made part of it from expanded metal."

The AZ training complex was even more challenging. "Based on the 3D drawings of the steel constructor, we engineered the sheet metal finish. One of the unique features was the chamfer, which did not run horizontally. By working in HiCAD with a 3D model, we were able to tackle and resolve the problems in good time. For example, we created special infill plates in order to be able to mount the sheet metal at all. These details only became clear in the model. As a result, the assembly sequence was also modified. The position numbering in HiCAD was adopted on the non-visible side of the profiles. With the accompanying layout plan, assembly was a piece of cake. In addition to the sheet metal, we also supplied a large number of water deflectors, wall sections and other customised profiles for this project."

Miranda is very satisfied with the software of ISD Group and working in 3D. "In 2D everything seems to fit. For example, a top view of water barriers with different slopes seems to fit perfectly, while in the 3D model you see that they are open. We therefore notice that more and more customers ask us to supply them with drawings in 3D. HiCAD and HELiOS enable us to respond to this perfectly. If we are involved in time, we can often come up with an alternative to make a design feasible in an efficient manner, sometimes with very minor adjustments to a profile. By drawing in HiCAD, we can process more orders by working smarter instead of harder.