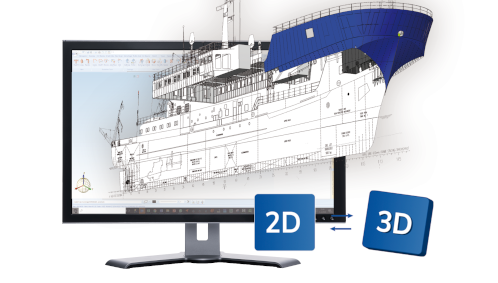

In the final analysis, the choice for 3D and 2D CAD software in one system is mainly a financial consideration. The number of manual operations is reduced and there is a better overview for those who overlay both types of drawings. But at least as important is the fact that the chance of errors decreases. After all, there is only one system in which the truth is visible.

Among companies in the metalworking industry, for example, it is common to work with several systems. If a file is received in 3D, it is usual to load it into 3D software for measuring purposes. Then you make the 2D production drawings in AutoCAD. However, nowadays it is perfectly possible to combine these two operations within one system. This also reduces time, the number of potential errors and ultimately costs. It also means that, as a user, you work with one package, one partner and therefore one point of contact. So is a CAD system in which both 2D and 3D drawings can be made expensive? That is the perception of many DGAs and draftsmen. But in practice, it is not that bad. Certainly for those who are prepared to look at the benefits and the investment picture in which all the advantages are included.

If you delve deeper into the drawing technical possibilities, the combination of 2D and 3D CAD software offers the necessary useful advantages. Because creating an overlap is easy, measuring and comparing files is also a piece of cake. This is partly because the software takes some of the measuring work off your hands. A company that spends a lot of time measuring every size when using two separate systems can have this done automatically in HiCAD.

Someone who, when making a drawing, is still under the impression that the inclusion of some dimensions might not be important, is counting outside the requirements that entrepreneurs place on their products. With the right software, a file supplied by a third party can easily be converted into a file that can be read by the system and then transformed into a production order. Thus, it is immediately clear whether something - when converting a drawing from 2D to 3D within one system - has a length of 50 mm or 100 mm.

Many companies have few repetitive jobs and often deliver customised products. If one job is slightly similar to another, a product library can be a solution. The reality is that companies do not often receive the same order. An order usually comes down to copying an example provided. Or adapting a certain profile. But in most companies, it is very doubtful whether the appropriate software is available. If the CAD software can help with the simple conversion from 2D to 3D and vice versa, convenience is suddenly very close at hand.

The easy switch between different files is there for the taking. This also applies to error reduction, a single point of contact, time savings and, at the end of the day, lower costs. Benefit from two types of CAD software in one.

Are you looking into renewing your CAD software? Download our CAD software buyers guide for help! It tells you about trends in CAD software, essential features, what to look for and how to make a smooth switch.